|

|

Product Details:

Detailed Introduction

Product name: Sulfur

Type: pure sulfur

Melting point: 119℃(300°F)

Boiling point: 444℃(832°F)

Density under 20℃(68°F): 2.05g/cm3

Application:

Sulfur is considered as a kind of harmful impurity and it is controlled as low as possible while steel-making.

Although sulfur has some negative effects, it is often used to improve the machinability of steel and it can also reduce the tool wear.

The solubility of sulfur in the steel is relatively low. The main purpose of sulfur in the liquid steel is the formation of a particular ingredient or complex inclusions to improve the steel machinability. Sulfur is usually added to the liquid steel in the form of pure sulfur, iron sulfur or pyrite. Because the density and boiling point of sulfur is pretty low, feeding sulfur wire is a kind of effective way to add the sulfur.

Specification

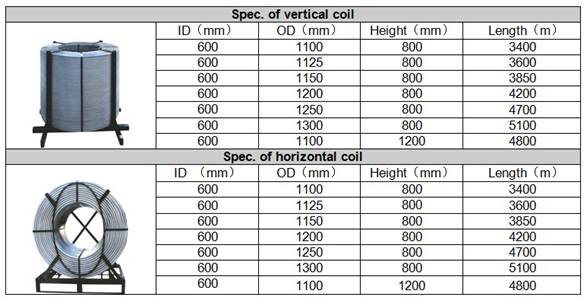

Dia 9mm cored wire is a kind of medium size wire, which is suitable for the ladle of capacity less than 20 MT and most of cast iron spheroidization

Φ9mm Cored wire Specification

* The above specifications can be adjusted upon request.

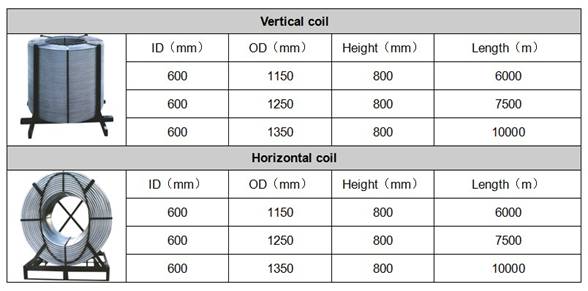

Dia 13mm cored wire is a typical size wire for steel industry, which is suitable for all kinds of steel ladles and alloys.

Dia 16mm cored wire is suitable for the alloy adding to the steel ladle of capacity more than 250MT.

Φ13mm - Φ16mm cored wire specification

* The above specifications can be adjusted upon request.

Diameter and fill rate

|

Products |

Diameter and fill rate(g/m) |

Application | ||

|

Φ9mm |

Φ13mm |

Φ16mm | ||

|

CaSi |

110 |

220 |

330 |

Steel desulphurization, deoxidization, inclusion modification and castability |

|

CaFe |

122 |

250 |

365 |

Low silicon Steel modification, inclusion modification and steel desulphurization, deoxidization, clogging prevention, castability |

|

AlCaFe |

150 |

300 |

For low silicon steel application, besides the function of CaFe cored wire but steel deoxidization and grain refinement | |

|

FeTi |

165 |

370 |

570 |

Microalloying and deoxidization |

|

FeBo |

200 |

550 |

825 |

Microalloying |

|

C |

140 |

205 |

Trimming addition, steel carbon adding | |

|

Mg |

60 |

140 |

210 |

Desulphurization and nodularisation |

|

FeSiMg |

235 |

335 |

Nodularisation | |

|

CaSiBa |

225 |

330 |

Inclusion modification | |

|

Al |

200 |

300 |

Deoxidization and grain refinement | |

|

S |

190 |

280 |

Re-sulphurising of free cuting steels | |

|

FeSi |

235 |

335 |

Nodularisation | |

|

The above fill rates can be adjusted upon request. The thickness of steel strip is 0.35~0.50mm, which conforms to the stipulation of GB716、GB3526、GB1323. The weight allowance for each 200g is no more than 2.5%. The joints for each 1000 meters are no more than 3. The cored wires are widely used for calcium treatment and microalloying in the ladle metallurgy, which have the advantages of element precise control and easy use. | ||||

Packing

Based on the design of feeding machine, cored wire coils can be made vertically or horizontally, With the special connector, the coils can be fed continuously, The packing also can be customized upon request.